PRODUCT APPLICATIONS

Applications include free flowing to

very viscous, particulated, hot and abrasive products. Fills a wide range

of container shapes in volumes from

15 mL to 2.5 gallons. Speeds to 100 containers per minute. Accuracies to

± 0.10% dependent upon dose size

and product.

STANDARD FEATURES:

- Four line X 20 back lit LCD display with easy use function keys housed in sealed NEMA 4 stainless steel enclosure.

- Easy operator interface access to filler control functions, including one pump speed and volume control for entire machine.

- Simple electronic control of no-drip product cut-off.

- Easy operator interface access to all automation functions including conveyor speed and container indexing. PLC includes built-in line management system to detect missing containers, or backups from downstream equipment.

- Non-volatile memory storage of all machine set-up data, with one-key "recipe" loading, for 50 product and container set-ups.

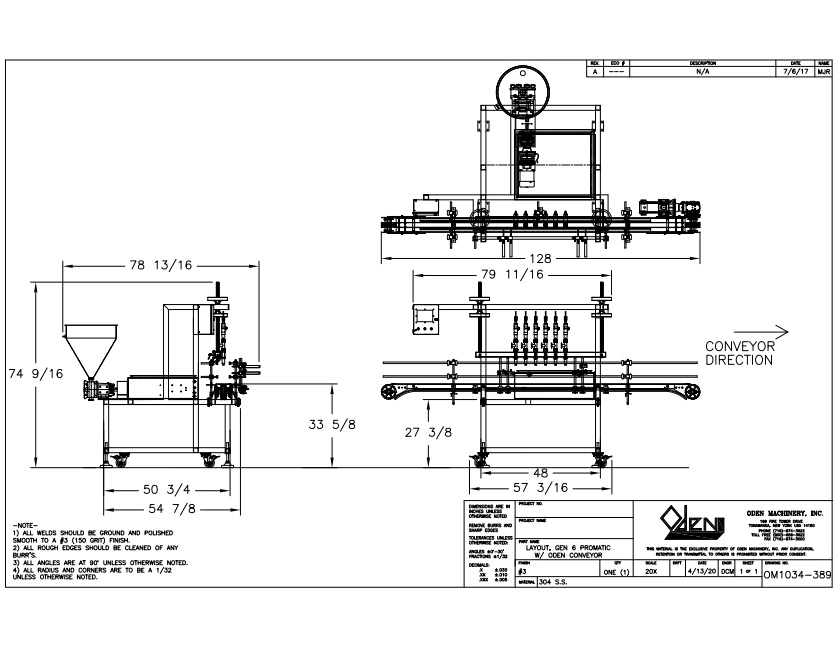

- Rugged 2" X 2" structural stainless steel welded machine base frame. Frame supports the stainless steel NEMA 4 pump drive/PLC enclosure, 20 gallon product reservoir, conveyor, nozzle rack system, and container indexing system.

- Sanitary stainless steel conveyor 10' long with 6" Delrin chain and variable speed DC motor drive. Includes four guide rails with no-tool adjustment hardware.

- Fluid flow pathway consisting of 20 gallon stainless steel reservoir, cover, and ball float level control system; Waukesha Universal Series size 30 sanitary pump; stainless steel product distributor; and six Oden Gen2 316L stainless steel positive shut-off nozzles.