Oden Process Group

Oden Process Equipment Group has the expertise, product experience and process engineering solutions you need to:

- Reduce labor costs.

- Enhance product quality.

- Increase production capacity.

- Decrease generation of waste and scrap.

FOOD & BEVERAGE ~ PERSONAL CARE ~ HOUSEHOLD ~ PHARMA ~ BIOTECH ~ CHEMICAL ~ INDUSTRIAL

We have industry wide experience in providing liquid processing machinery solutions that meet sustainability requirements.

Our liquid packaging team offers process plant machinery backed with over 3 decades of industry-leading innovation in designing and engineering solutions for liquid products applications.

Liquid Process Equipment

Liquid Process Equipment

Oden Corporation, in alliance with Green Frontier, offers liquid products processing machinery that optimizes profits and at the same time, reduces impact on the environment.

Improve your sustainability performance with these benefits:

- Reduced labor costs

- Enhanced product quality

- Increased production capacity

- Decreased generation of waste and scrap

Liquid Blending Systems

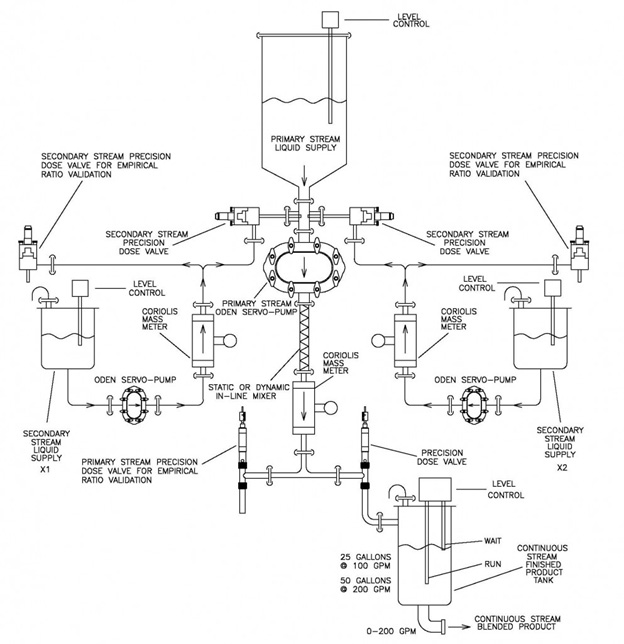

Gen 3 Mass/ Blend Continuous Stream Digital Building

The MASS/BLEND® Continuous Stream Digital Blending System represents a quantum leap forward in blending system design, eliminating many of the problems associated with large liquid batch preparation and providing more compounding flexibility, faster product turnarounds, shorter practical run capabilities and superior product quality.

The MASS/BLEND® Continuous Stream Digital Blending System represents a quantum leap forward in blending system design, eliminating many of the problems associated with large liquid batch preparation and providing more compounding flexibility, faster product turnarounds, shorter practical run capabilities and superior product quality.

Industry applications:

- Food, Dairy and Beverage Plants

- Personal Care Products Industry

- Household Products Industry

- Chemical Products Industry

- Pharma and Biotech Products Industry

- Industrial Products Industry

How it works:

- Each liquid stream is individually dosed to a common location at a net flow rate greater than the maximum take-away rate.

- A dose is “on-off” or digital. It is produced by a servo–PD pump–mass meter “module”.

- Each stream is dosed to a correct mass proportion.

- Each stream starts and stops simultaneously.

- The system can be started or stopped at each dose interval — typically every 5 seconds.

- The system is inherently accurate, stable, self monitoring, self correcting.

- The system automatically adapts to changes in take away flow rates without re-calibration or stream flow adjustment.

The appeal and merit of the Mass/Blend continuous stream blending system, as distinct from a batching system, is clear. The ability to eliminate large liquid product batch preparation and holding tanks leads allows for small system volume, more product compounding flexibility, faster product species turn around, smaller and shorter practical run capabilities and a substantially lower capital asset commitment. Continuous stream in-line blending also yields superior product quality, and eliminates the “wall” between liquid products processing and liquid products packaging, as well as greatly reduce waste, cleanup time and effluent volumes.

Features and Benefits:

- Ready for Connection

- No Filler Starvation or Startup Problems

- Pre-Engineered Dosing “Modules”

- 0 to 250 GPM Continuous Stream Liquid Flow Capability

- “Cycle by Cycle” Tuning and Monitoring of Flow Meters During Process

- Operate with All Types of Liquids – Low Viscosity to High

- No Forced Changes in Present Batch Formula Streams

- Requires Only Small Product Quantities in the Pipeline

- All Blended Product Can Be Utilized

- Proven Technology Components

- PC/PLC Controls

- Mass Flow Meter Based

- No PID Loops

- No Start/Stop Problems or Penalties

- Exceptionally Low System Volume

- High Accuracy Inherent with mass Flow Meters

- Up to 0.15 to 0.25% Accuracy Dependent upon Dose Size and Product

How can Digital Blending blur the line between processing and packaging?

- No mixing tanks required

- Reduced consumption of plant floor space

- Quick availability of product

- Real time batching — no aging effects

- Easier handling

- Direct mixing of the products in the pipeline

- Faster changeover

- Maximum flexibility for “future FOG”

- Greater product consistency and reproducibility

- Precise mass flow meters – high accuracy

- Inherent 100:1 scalability of the batch process

- Make only what you need — no waste

- Shorter runs become practical

- Tighter bundle to consumer demand

- Inherent and fast CIP

- Reduced component waste

- Reduced effluent volumes

Turnkey Liquid Product Transfer Systems

Oden Process Equipment Group supplies turnkey transfer systems from raw material bulk supply to blending equipment and batching vessels and on to your packaging lines. Systems are available for flow rates ranging from microliters to 300 gallons per minute without sacrificing accuracy.

Rugged, durable and flexible designs are available for a wide range of viscosities, temperatures, particulate products and are engineered for your unique chemical compatibility requirements.

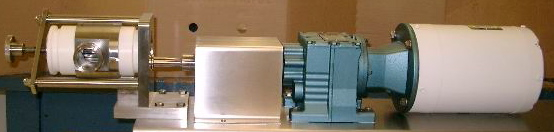

Solutions include micro pump, CleanGear® sanitary servo pump, rotary lobe, progressive cavity and air operated diaphragm pump configurations.

Available with stainless steel bases, NEMA 4 washdown enclosures, and Class 1, Division 1, Group D explosion proof construction.

Electronic controls and software, level control integration and actuated valves to complete turnkey installations.

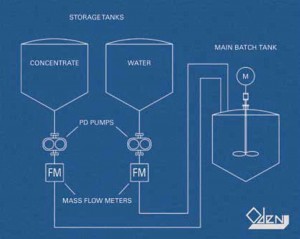

Automated Batch Addition Systems

- Reduce batch cycle times and associated operating costs

- Enhance bulk product responsibility

- Improve adherence to established specifications

- Boost accuracy of bulk additions

- Fully and semi-automatic single or multiple channel precision liquid product metering – pretested, performance guaranteed

- Mass meter and loss in weight scale based systems for net weight applications or SPC requirements

- Simultaneous bulk raw ingredient addition

- Precision metering and dosing of color, fragrance, vitamins, actives and claim ingredients

- Concentrate dilution

- Your choice of factory standard OEM component brands

- Full installation, integration and commissioning support