Blending and Batching Machines

Oden Process Equipment Group: MASS/BLEND

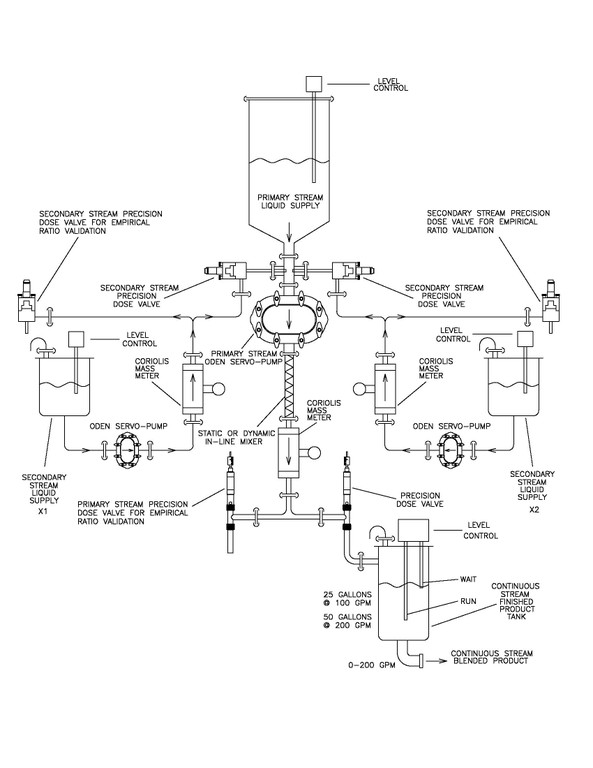

CONTINUOUS STREAM DIGITAL BLENDING SYSTEMS

The appeal and merit of the Mass/Blend continuous stream blending system, as distinct from a batching system, is clear. The ability to eliminate large liquid product batch preparation and holding tanks leads allows for small system volume, more product compounding flexibility, faster product species turn around, smaller and shorter practical run capabilities and a substantially lower capital asset commitment. Continuous stream blending also yields superior product quality, and eliminates the "wall" between liquid products processing and liquid filling machines, as well as greatly reduce waste, cleanup time and effluent volumes.

BASIC CONCEPTS

How It Works - A Brief Look

- Each liquid stream is individually dosed to a common location at a net flow rate greater than the maximum take-away rate.

- A dose is "on-off" or digital. It is produced by a servo--PD pump--mass meter "module".

- Each stream is dosed to a correct mass proportion.

- Each stream starts and stops simultaneously.

- The system can be started or stopped at each dose interval -- typically every 5 seconds.

- The system is inherently accurate, stable, self monitoring, self correcting.

- The system automatically adapts to changes in take away flow rates without re-calibration or stream flow adjustment.

GENERAL REQUIREMENTS

- PC/PLC Controls

- Mass Meter Based

- No PID Loops

- No Start/Stop Problems or Penalties

- Exceptionally Low System Volume

- Up to 0.15 to 0.25% Accuracy Dependent upon Dose Size and Product

TYPE OF PRODUCT

- No Filler Starvation or Startup Problems

- Pre-Engineered Dosing "Modules"

- 0 to 250 GPM Continuous Stream Capability

- "Cycle by Cycle" Tuning and Monitor

- Operate with All Types of Liquids - Low Viscosity to High

- No Forced Changes in Present Batch Formula Streams

- All Blended Product Can Be Utilized

- Proven Technology Components

HOW CAN DIGITAL BLENDING BLUR THE LINE BETWEEN PROCESSING AND PACKAGING?

- Reduced consumption of plant floor space

- Real time batching -- no aging effects

- Faster changeover

- Maximum flexibility for "future FOG"

- Greater product consistency and reproduce-ability

- Inherent 100:1 scaleability of the batch process

- Make only what you need -- no waste

- Shorter runs become practical

- Tighter bundle to consumer demand

- Inherent and fast CIP

- Reduced component waste

- Reduced effluent volumes

WANT TO KNOW MORE?

Call for a technical "White Paper" which explores these technical methods in depth. Download the GEN3 MASS/BLEND brochure.

Email sales@odenmachinery.com. Call 716-874-3000. Request a Quote.

PRODUCT TESTING AND PERFORMANCE GUARANTEE

The Filling Accuracy Capability Statements appearing on this website describe general machine capabilities and are not guarantees. Oden will guarantee machine performance in writing, upon the positive conclusion of testing done with your products and containers. Also check out our bottle capping machines and dairy filling machines for your other packaging needs.

BUY RISK FREE: See our Product Testing and Performance Guarantee

Call now for a quick response to your application questions.

Call 716-874-3000 or 800-658-3622 (US & Canada).