Investing in the right liquid filling machine can make or break your production line—too little capacity and you’ll bottleneck growth; too much, and you’ll tie up capital in equipment you don’t need. Costs stretch from a few thousand dollars for a tabletop workhorse to six figures for a high-speed, hands-off system, and every dollar buys a different blend of speed, precision, and reliability.

Understanding how those price tags map to real-world performance empowers you to strike the perfect balance between budget and throughput and protect your bottom line as you scale.

Average Cost of Liquid Filling Machines

Across the liquid filling industry, machines generally start around $1,000 and can climb past $100,000, with most businesses landing somewhere between $5,000 and $50,000 based on their production goals and level of automation.

| Machine Type | Price Range | Typical Throughput |

|---|---|---|

| Manual | $1,000‒$5,000 | 20‒50 bottles/hour |

| Semi-Automatic | $5,000‒$20,000 | 50‒200 bottles/hour |

| Automatic | $20,000‒$100,000+ | 200‒3,000+ bottles/hour |

On the low end, manual units keep things simple and inexpensive. Mid-range semi-automatic models balance operator interaction with faster fill cycles. At the top, fully automatic lines deliver high throughput but require a more significant capital outlay for advanced mechanics and control systems.

Manual Liquid Filling Machine Price on Average

Manual liquid filling machines are the most accessible options for startups, craft producers, and laboratories testing new formulations. Priced between approximately $1,000 and $5,000, these basic units consist of a filling head, simple pump or gravity-feed system, and a manual trigger mechanism.

Because an operator must position each container and activate the fill for every cycle, throughput typically sits between 20 and 50 containers per hour—enough for small batches but limiting for larger runs. Additionally, the straightforward design means fewer electronic components and lower maintenance costs, which keeps the initial price tag modest.

However, manual operation can introduce inconsistencies in fill volume, so quality control relies heavily on operator skill.

Semi-Automatic Liquid Filling Machine Price on Average

Stepping up in both speed and price, semi-automatic fillers give you a push-button approach without the complexity of a fully integrated line.

These machines range from about $5,000 to $20,000 and are built around an automated dispensing system paired with a conveyor or carousel that positions containers under the fill head. An operator still places and removes the containers but simply presses a footswitch or button to initiate each cycle. This design boosts throughput to roughly 50–200 containers per hour, depending on the model and operator pace.

The added mechanical and electronic elements improve consistency and reduce operator fatigue, which accounts for the higher cost compared to manual units.

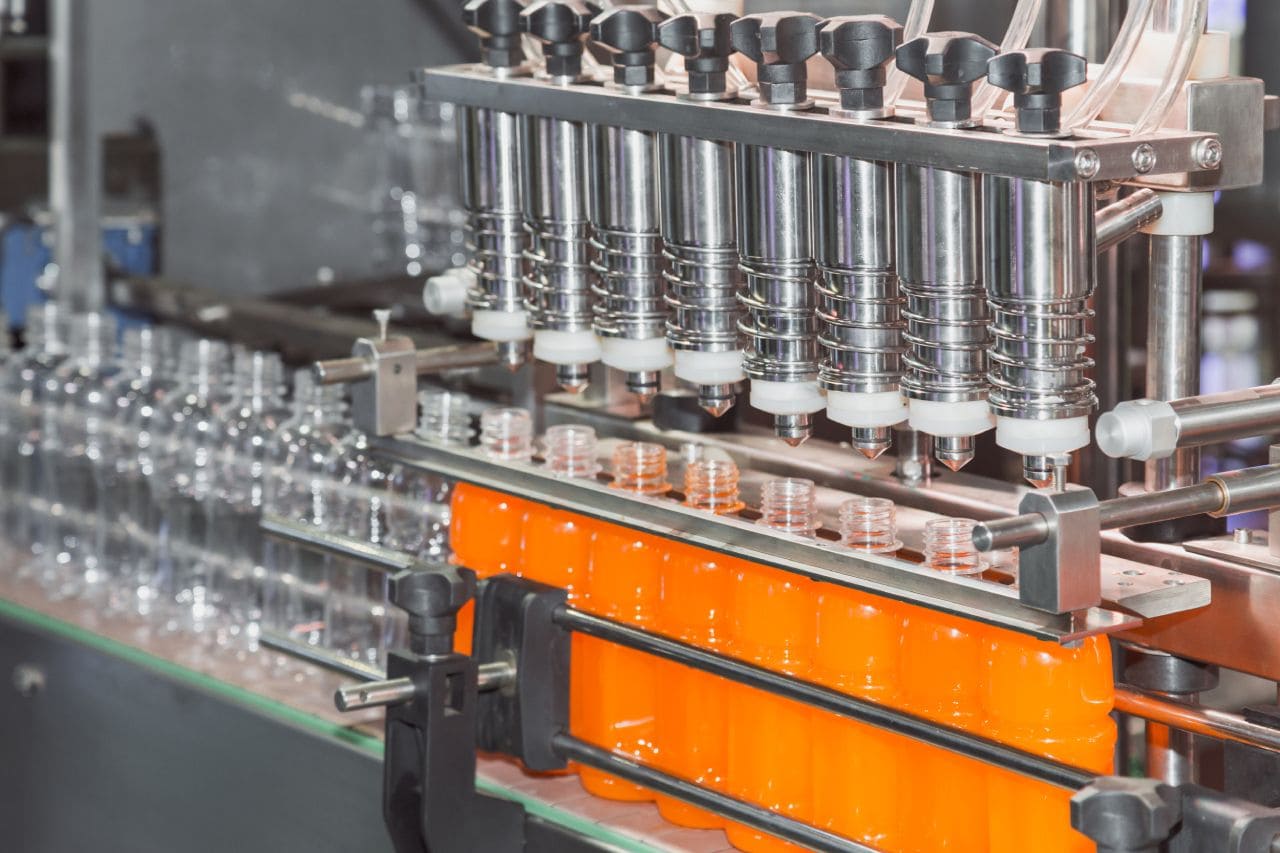

Automatic Liquid Filling Machine Price on Average

Fully automatic liquid filling systems represent the peak of efficiency and the upper end of the price spectrum. You can expect to pay anywhere from $20,000 for entry-level lines to well over $100,000 for high-speed, multi-head configurations with advanced cleaning and control features.

These machines feed, fill, and discharge containers with minimal human intervention, achieving speeds of 200 to 3,000+ units per hour. Precision servo motors, programmable logic controllers (PLCs), integrated conveyors, and built-in clean-in-place (CIP) systems all contribute to the elevated price.

While the upfront investment is substantial, the payoff comes in labor savings, reduced waste, and consistent, scalable production.

13 Factors Influencing Liquid Filling Machine Price

Every feature and specification you add to a liquid filling machine becomes a lever on its price tag. From the size of the frame to the sophistication of sensors, each choice carries a cost impact.

Consider these factors as you tailor your purchase to the exact needs of your operation to maximize value without overspending on unnecessary bells and whistles.

1. Filling Technology & Accuracy

Whether a machine measures by volume, weight, or time-pressure determines both performance and cost.

Volumetric systems use calibrated pistons or cylinders for repeatable fills, offering solid accuracy without breaking the bank. Gravimetric fill heads, which weigh each container to achieve exact volumes, add more expensive load cells and calibration routines. Time-pressure fillers rely on carefully tuned pressure settings to push liquid at a known rate—a lower-cost option but prone to variation with fluid properties.

Machinery with tighter tolerances and less fill variance often commands higher prices because of more advanced control algorithms and components.

2. Production Speed & Capacity

Speed is money in manufacturing, but increasing throughput demands robust engineering. Single-head machines might fill at a modest pace, while multi-head setups multiply output and machine complexity. Faster conveyors require stronger motors and precision synchronization, leading to higher engineering and manufacturing costs.

If you plan to ramp production quickly, investing in a higher-capacity frame from the start is more cost-effective than costly upgrades later. Conversely, oversizing your line for current needs can leave capital idle, so match your speed requirements carefully to your budget.

3. Level of Automation

From hand-crank simplicity to hands-off continuous operation, automation levels dictate the number of parts and the complexity of software needed.

Manual machines feature minimal wiring and straightforward controls. Semi-automatic units add footswitches, sensors, and rudimentary PLCs. Fully automatic lines integrate multiple sensors, human-machine interfaces, safety interlocks, and recipe-driven controls.

Each layer of automation boosts reliability and repeatability but adds to the bill of materials, engineering hours, and validation time.

4. Liquid Properties

The nature of your fluid—if it flows like water or glues itself like honey—has a direct bearing on component selection and cost.

Thin, free-flowing liquids can use standard pumps and nozzles, keeping costs lower. Conversely, viscous, foaming, or shear-sensitive fluids require specialized piston pumps, positive displacement systems, or anti-foam regulators, all of which come at a premium. Corrosive or abrasive materials demand high-grade stainless steel, exotic alloys, or food-grade coatings, further increasing expenditure.

Custom material compatibility testing and validation can also extend lead times and add to upfront costs.

5. Container Types & Tooling

Every shape and size of bottle, jar, or pouch needs its own handling and filling setup. For example, simple cylindrical bottles are low-cost, but irregular shapes, slender necks, or soft pouches require custom-engineered tooling.

Change parts such as nozzles, grippers, and guide rails ensure accurate placement and fill for each container variant. Tooling kits often carry one-time design and machining fees, which add to the initial investment but can be amortized over large production volumes.

6. Materials & Build Quality

A machine’s frame material, finish, and construction standards reflect both durability and price.

Food, beverage, and pharmaceutical lines typically require sanitary-grade 304 or 316 stainless steel, polished welds, and FDA-approved hoses and seals. These standards resist corrosion, simplify cleaning, and comply with regulatory requirements, but they cost more to fabricate. Lower-cost fillers may use painted carbon steel or mixed materials, which save money upfront but can incur higher maintenance or replacement costs over time.

7. Additional Features

Every add-on—from integrated capping heads and labelers to vision systems for fill verification—pushes price upward.

Built-in CIP modules streamline sanitization at a cost of pumps, valves, and piping. Recipe-driven touchscreen human-machine interfaces (HMIs) make changeovers faster but require custom software and training. Even remote monitoring or Industry 4.0 connectivity can add thousands by including networking hardware and cloud subscriptions.

8. Brand & Support

Established original equipment manufacturers (OEMs) often charge a premium for proven reliability, global service networks, and comprehensive warranties. Lesser-known or regional manufacturers may undercut prices but can carry higher risks in parts availability and technical support.

Warranty length, spare parts packages, and on-site training offerings also all factor into the overall price of ownership and should be weighed alongside the sticker cost.

9. Machine Size & Footprint

The physical dimensions of a filling machine affect not only the floor space it occupies but also the materials and shipping logistics.

Larger frames require more steel, bigger motors, and broader conveyor belts, all of which contribute to higher manufacturing costs. If your plant has space constraints, a compact design might command a premium for clever engineering in a smaller package.

In addition, on-site installation for oversized machines can require special rigging and assembly services, boosting total project cost.

10. Used vs. New

Opting for a pre-owned or refurbished machine can save 30–50% off the price of a new unit.

Choosing a used liquid packaging system demands careful inspection and, in some cases, a service contract to mitigate downtime risks. You must also account for wear and tear on mechanical components, potential obsolescence of electronic controls, and the availability of spare or replacement parts.

Always work with experienced, trustworthy suppliers when sourcing used liquid filling machines. Reputable refurbishers often rebuild pumps, replace seals, and recalibrate systems, and they also offer on-site training, warranties, and installation services that approach those of new machines.

11. Controls & Instrumentation

Basic pushbuttons and analog gauges come cheap, but advanced PLCs, touchscreen HMIs, and proportional-integral-derivative (PID) control loops add sophistication and cost. High resolution flow meters, pressure transducers, and temperature probes ensure tight process control, but each instrument carries its own price tag. Custom software packages that log data, trigger alarms, and support batch reports require engineering hours and licensing fees. For operations bound by regulatory compliance, validated software and secure data storage can also influence the price.

12. Customization Level

Standard machines follow factory specs; custom builds adapt to your unique workflow and product requirements.

Customization can include specialized conveyor layouts, multiple fill heads, integrated upstream/downstream equipment, or exotic materials. Every bespoke adjustment—from unique catch trays to specialized safety guarding—adds engineering design work and machining time. The deeper the level of customization, the more you pay for one-off engineering labor and non-standard parts.

13. Logistics & Shipping

Shipping large industrial machines often involves freight costs, customs duties, and specialized crating. Overseas shipments incur sea freight charges, port handling fees, and inland transport costs.

Accelerated delivery or partial assembly at the factory can shorten installation timelines but increase shipping and labor expenses. Local deliveries may seem cheaper, but if a regional distributor has limited stock, you might sacrifice lead time or pay premium surcharges for expedited transport.

Smart Strategies to Save on Your Liquid Filling Machine Investment: 7 Cost-Saving Tips

Maximizing value doesn’t always mean choosing the cheapest machine. Instead, a thoughtful approach to sourcing, negotiation, and lifecycle planning can unlock substantial savings without sacrificing performance.

1. Right-Size Your Investment

Assess your current production volume and realistic growth projections before choosing a machine. Overbuying capacity can tie up capital in underutilized equipment, while underestimating future needs forces costly upgrades.

A phased approach—starting with a mid-level model that can be scaled via modules—lets you grow with demand. Pair this with a solid forecasting process, and you’ll avoid both bottlenecks and wasted budget.

2. Consider Refurbished Equipment

Certified refurbished machines often deliver near-new performance at a significantly lower cost. Reputable refurbishers strip down the equipment, replace worn parts, and update controls to current standards. Most come with limited warranties that mirror those on new machines, providing a safety net against unexpected failures.

When evaluating used options, prioritize vendors with transparent rebuild documentation and proven service histories.

3. Bundle Packages

Coordinating multiple vendors separately often adds hidden costs in engineering and project management. Instead, consider bundling.

Buying a turnkey line—complete with filling, capping, labeling, and inspection all from one OEM—can reduce per‑unit costs and simplify integration. Suppliers are more inclined to offer discounts when you commit to multiple pieces of equipment in a single order. Bundles also streamline installation, training, and service contracts, saving time and money during deployment.

4. Negotiate Terms

Don’t accept sticker prices as final. Speak candidly with suppliers about your budget constraints and ask for concessions on list prices, extended warranties, or added service hours.

Timing matters. Vendors often offer year-end or off-season discounts when demand is lower.

Be prepared to negotiate demo or floor models that require only cosmetic touch-ups in exchange for deeper savings. Remember, everything from installation fees to training sessions is negotiable, so bundle and push for the best all-in-one package.

5. Leverage Trade-In Value

A clear trade-in agreement can make a sizable dent in your upfront investment.

If you’re upgrading from an older filling system, inquire about trade-in credits that offset the cost of your new machine. OEMs often refurbish or resell used equipment, so they may offer significant allowances toward your purchase. Trading in also reduces your disposal headaches and can speed up the lead time for delivery of your new unit.

Before negotiating trade-in terms, have your current machine professionally assessed so you know its fair market value.

6. Choose Modular Designs

Modular machines allow you to expand functionality down the road without replacing the entire system. Start with core filling heads, then add capping, labeling, or inspection modules when production warrants. This phased approach helps you spread capital costs over time and align upgrades with real growth.

Plus, modular designs often share common parts and controls, simplifying maintenance and reducing spare-part inventories. The flexibility to adapt seamlessly to new container types or fill recipes can deliver big savings over the equipment’s lifespan.

7. Plan for Maintenance

A well-maintained machine runs longer and costs less to own. Factor preventive maintenance kits, spare-parts packages, and service contracts into your purchase negotiations. Regularly scheduled tune-ups catch wear before it causes unplanned downtime, protecting your production schedule and revenue.

Many OEMs offer discounted service rates or bundled maintenance plans when you purchase upfront. Investing in training for your in-house technicians can also further reduce reliance on premium-rate emergency calls and keep operating costs predictable.

Find Trusted, High-Quality Used Liquid Filling Machines at Oden Machinery

Choosing the ideal liquid filling machine requires matching performance, durability, and future growth to your unique needs. With a clear understanding of cost drivers and savvy purchasing strategies, you’re poised to make a high-impact investment.

At Oden Machinery, we specialize in supplying used liquid packaging equipment that meets the highest standards of quality, performance, and reliability. Every machine is thoroughly inspected, refurbished, and supported with expert service to ensure your production line operates smoothly and efficiently. Whether you’re looking for a single machine or want to completely overhaul your liquid filling line, we have the equipment and expertise to match your needs.

Contact us today to learn more about our available inventory of used liquid filling machines and find the perfect solution for your operation.