As sustainability becomes a core focus for modern industries, the liquid packaging sector is undergoing a dramatic transformation. Eco-friendly packaging machines are emerging as a critical driver of this shift because they offer a sustainable alternative to traditional equipment. These machines not only reduce the environmental impact of packaging operations but also enhance operational efficiency and brand reputation.

By integrating cutting-edge technologies and sustainable materials, eco-friendly packaging machines help manufacturers reduce their carbon footprint, comply with evolving regulations, and meet the rising consumer demand for environmentally responsible practices in the liquid packaging industry.

The Environmental Impact of Traditional Liquid Packaging Machines

Conventional liquid packaging equipment has long relied on outdated technologies and materials that contribute significantly to environmental degradation. They typically operate with high energy consumption and draw heavily on electricity and fossil fuels to power motors, pumps, and heaters. Additionally, many systems are not optimized for precision, which leads to unnecessary product spillage, overfilling, and excessive use of packaging materials.

Traditional machines often utilize plastic packaging that is neither biodegradable nor easily recyclable. These plastics contribute to the growing global problem of landfill overflow and ocean pollution.

Furthermore, frequent maintenance requirements and a lack of modularity result in parts being discarded prematurely, adding to industrial waste. Their inefficient designs not only drain resources but also leave a considerable carbon footprint throughout their lifecycle, from manufacturing and operation to disposal.

An Introduction to Sustainable Liquid Packaging: Common Characteristics of Eco-Friendly Packaging Machines

Eco-friendly liquid packaging machines represent a new generation of technology that prioritizes both performance and environmental responsibility. This type of equipment is engineered to meet high-volume production demands while minimizing ecological impact. They are part of a broader movement in manufacturing that emphasizes sustainability, innovation, and efficiency.

Here are a few characteristics that identify a liquid packaging machine as more eco-friendly and sustainable than its traditional counterparts.

Use of Biodegradable or Recyclable Packaging Materials

Eco-conscious machines are specifically designed to work with a range of sustainable materials such as PLA-based biodegradable films, recyclable PET containers, and paper-based packaging. For example, a juice manufacturer may opt for recyclable tetra packs or compostable pouches, which the right machines can handle without compromising fill accuracy or sealing strength.

Precision Filling Methods That Minimize Waste

Technologies like gravity fillers, piston fillers, and vacuum fillers ensure accurate dispensing of liquids into containers.

A gravity filler is ideal for thin, water-like liquids, reducing the chance of overflow, and piston fillers are great for viscous products such as lotions or sauces, offering controlled volume fills. Alternatively, vacuum fillers are commonly used for delicate or foaming products, preventing waste by maintaining even fill levels.

Multi-Functional & Modular Design

Many of today’s eco-friendly liquid packaging machines are designed to perform multiple operations in a single pass, from filling to capping and labeling. This integration reduces the need for multiple machines, lowers power usage, and minimizes the production footprint.

A modular design also allows for easy upgrades or configuration changes, which helps extend the lifespan of the machine, further reducing the need for full replacements.

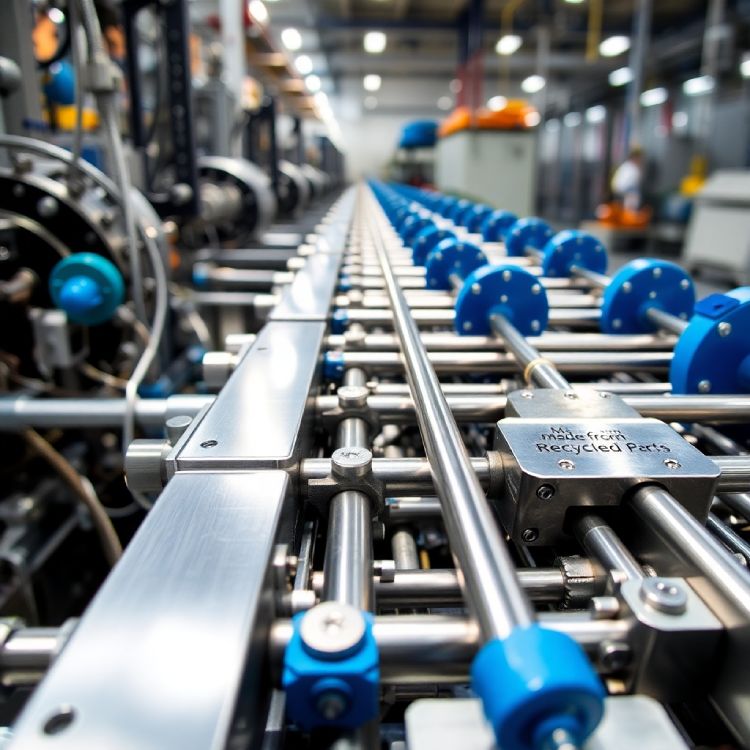

Sustainable Construction & Lifecycle Efficiency

Eco-friendly packaging machines themselves are often built from recyclable or energy-efficient components, such as stainless steel with low-impact coatings, energy-saving motors, and intuitive control panels that require minimal power. In addition, they are designed for easy cleaning and maintenance to reduce water and chemical usage as well as increase uptime.

13 Benefits of Switching to Eco-Friendly Liquid Packaging Machines

Making the transition to sustainable packaging technology is better for the planet and makes solid business sense. Modern eco-friendly machines combine environmental benefits with operational and financial efficiencies that support long-term growth.

1. Cut Down on Carbon Emissions

Advanced packaging machines are designed with energy-efficient components that require less electricity, resulting in a lower carbon footprint. Variable frequency drives and servo motors, for example, adjust energy usage to match demand, reducing unnecessary energy waste. Over time, companies see significant reductions in emissions tied to their manufacturing operations.

2. Minimize Packaging & Product Waste

In high-volume settings, even a small reduction in waste per unit adds up to substantial material savings.

Thanks to precision dispensing technologies, waste from overfills, leaks, or packaging damage is dramatically reduced. Additionally, smart sensors and automated adjustments ensure consistent accuracy, which is essential for both environmental impact and cost control.

3. Preserve Vital Natural Resources

Eco-friendly machines reduce the use of water, electricity, and raw materials through optimized operation cycles and improved process controls. Water-based cleaning systems that recycle wash fluids and have minimal rinse requirements for changeovers conserve thousands of gallons annually. The result is a more responsible use of global resources.

4. Use Packaging That Breaks Down or Gets Reused

These machines support biodegradable, compostable, and fully recyclable packaging types, contributing to circular economy goals. For instance, compostable films used in personal care products can decompose naturally, reducing landfill dependency.

Some machines are also compatible with post-consumer recycled (PCR) materials, which further encourages reusability.

5. Lower Energy Bills & Reduce Consumption

Eco-efficient machines often consume 20‒30% less energy than legacy models, thanks to innovations like automatic shut-off, low-energy sealing systems, and efficient heat recovery. These features not only help the planet but also translate to lower operational costs over time.

6. Spend Less on Raw Materials

With greater accuracy and material efficiency, businesses can cut down on the quantity of packaging and product used per unit. Spending less on raw materials leads to noticeable reductions in purchasing costs for items such as films, bottles, and caps, especially when bulk buying is involved.

7. Decrease Labor & Training Needs

Automated systems streamline operations and reduce the number of operators required on the production floor. User-friendly interfaces also require less training time, allowing staff to be more productive and focused on higher-value tasks.

8. Reduce Shipping Costs Through Better Design

Lighter, more compact packaging made possible by eco-friendly machines leads to lower transportation costs and carbon emissions. This reduction in shipping costs is especially beneficial for companies with widespread distribution networks or e-commerce operations.

9. Build a Responsible & Respected Brand

Eco-conscious consumers are more likely to support companies committed to sustainability. Using green equipment and practices can enhance a business’s public image, attract new customer segments, and improve stakeholder trust.

10. Boost Speed & Reduce Downtime

Modern machines are built for quick changeovers, smart diagnostics, and adaptive performance. A boost in speed and reduction in downtime improves efficiency, minimizes production interruptions, optimizes throughput, and allows companies to scale more effectively.

11. Safeguard Products & Reduce Returns

Accurate filling and secure sealing systems improve product integrity and reduce the chances of spoilage or damage in transit. By safeguarding products, eco-friendly packaging equipment can lead to fewer customer complaints and returns, improve profitability, and boost overall customer satisfaction.

12. Stay Ahead of Environmental Regulations

Compliance with local and international standards is easier with eco-friendly machines, which often come pre-certified or built to meet specific sustainability benchmarks. When liquid packaging equipment is designed with sustainability in mind, it reduces the risk of non-compliance fines and delays.

13. Adapt to a Wide Range of Products & Containers

Eco-friendly liquid packaging machines are built with flexibility in mind to allow for quick adaptation to different bottle types, materials, and viscosities. Whether filling water, oils, syrups, or sanitizers, the same machine can often handle a diverse product line with minimal modification.

How to Choose the Right Eco-Friendly Packaging Machine for Your Liquid Packaging Business

Selecting the right eco-friendly packaging machine is a critical decision that can influence your production efficiency, sustainability outcomes, and long-term profitability. Consider the following factors when making your choice.

Match the Machine to Your Product & Output Needs

Consider the type of liquid product (including its viscosity, foaming potential, and sensitivity) and your daily output volume. For instance, a piston filler is better for thicker products like shampoos or sauces, while gravity fillers work best for water-thin liquids.

Additionally, make sure the machine is scalable to future production increases.

Prioritize Sustainable Construction Materials

Look for equipment made with long-lasting, recyclable components like stainless steel, aluminum, and modular parts. These machines reduce maintenance costs and environmental impact over time and are often easier to sanitize and service.

Consider Buying Used Machines

Purchasing a high-quality used packaging machine can lower upfront costs while supporting sustainability by extending equipment lifecycles and reducing the waste required to manufacture new equipment. Many used machines still offer reliable performance and can include energy-efficient features. Just ensure the machine has a solid maintenance record and is compatible with your product and output needs.

Analyze & Compare Energy Requirements

Choose models with energy-saving technologies, and review consumption data under normal operating conditions. High-efficiency motors, automatic sleep modes, and LED control panels can all reduce ongoing energy costs.

Evaluate Usability & Maintenance Efficiency

A good machine should be intuitive for operators, with a user-friendly interface and quick-change features. Consider ease of disassembly for cleaning, time between required maintenance intervals, and availability of remote diagnostics or support.

Research Customer Feedback & Industry Success Stories

Read case studies, industry testimonials, and verified reviews to gauge real-world performance and return on investment (ROI). Look for companies in similar industries or with similar output needs to understand how a specific machine might perform in your setting.

Consult with Liquid Packaging Experts

Before finalizing your choice, talk to experienced liquid packaging consultants or manufacturers who specialize in sustainable solutions.

These experts can evaluate your production environment, product specifications, and business goals to recommend a tailored solution that balances cost, performance, and eco-friendliness. They can also guide you through regulatory compliance, grant or subsidy opportunities for green technologies, and potential upgrades to enhance your sustainability roadmap over time.

By leveraging their insight, you reduce costly trial-and-error and gain a long-term partner in your packaging evolution.

Future Outlook: Expected Growth in Sustainable Liquid Packaging

The growth of sustainable liquid packaging shows no signs of slowing down. As global awareness around climate change and plastic pollution increases, businesses face growing pressure from consumers, governments, and investors to adopt environmentally sound practices. It’s especially true in the liquid packaging sector, where the demand for low-impact, high-efficiency solutions is stronger than ever.

Technologies will continue to evolve, with artificial intelligence (AI) and the Internet of Things (IoT) driving smarter, more adaptable packaging lines that reduce waste in real time. Solar-powered machines, automated efficiency monitors, and real-time sustainability dashboards will become more common. Meanwhile, material science advancements will expand the range of biodegradable and recyclable materials that machines can support, enabling even greater reductions in environmental impact.

For liquid packaging manufacturers, the future is green, efficient, and driven by innovation. Companies that invest in eco-friendly machinery now position themselves ahead of the curve—ready to meet future regulations, align with environmental, social, and governance (ESG) goals, and appeal to the growing demographic of eco-conscious consumers.

Invest in Sustainability with Eco-Friendly Liquid Packaging Machines from Oden

Eco-friendly liquid packaging machines represent a smarter, more efficient, and future-ready way of doing business. For companies in the liquid packaging industry, adopting sustainable practices through advanced machinery is a win for the planet, the bottom line, and the brand.

Ready to reduce waste, improve efficiency, and lead in sustainability? We’re here to help.

At Oden Machinery, we specialize in supplying used liquid packaging equipment that meets the highest standards of quality, performance, and reliability. Every machine is thoroughly inspected, refurbished, and supported with expert service to ensure your production line operates smoothly and efficiently.

Whether you’re looking for a single eco-friendly liquid filler or want to design a complete sustainable packaging system, we have the equipment and expertise to match your needs.

Contact us today to learn how our eco-friendly liquid packaging solutions can help your business thrive.