Gravity Liquid Filling Machines

GRAV/TRONIC® Gravity Filler Machine

Benchtop & Automatic Volumetric Gravity Liquid Filling Machines

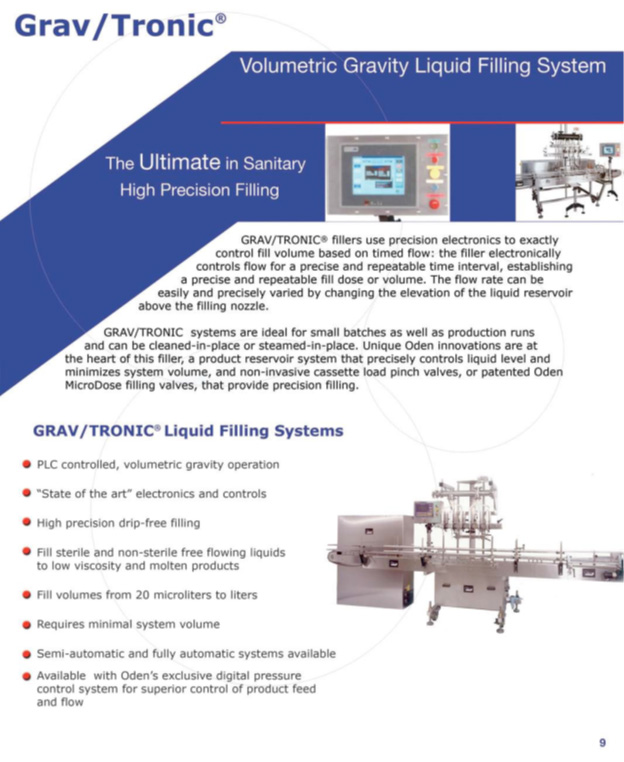

The Ultimate in Sanitary High Precision Filling

GRAV/TRONIC® gravity filler machines use precision electronics to exactly control fill volume based on timed flow. The flow rate can be easily and precisely varied by changing the elevation of the liquid reservoir above the filling nozzles. Additionally, these gravity filling machines include:

- Accurate filling from microliters to liters.

- Clean-in-place or steam-in-place.

- Requires minimal system volume.

- Non-invasive cassette load pinch valves; or optional patented Oden Microdose® filling valves.

GRAV/TRONIC® Gravity Filling Machine

Benchtop & Automatic Volumetric Gravity Liquid Filling Machines

The Ultimate in Sanitary High Precision Filling

GRAV/TRONIC® gravity filler machines use precision electronics to exactly control fill volume based on timed flow. The flow rate can be easily and precisely varied by changing the elevation of the liquid reservoir above the filling nozzles. Additionally, these gravity filling machines include:

- Accurate filling from microliters to liters.

- Clean-in-place or steam-in-place.

- Requires minimal system volume.

- Non-invasive cassette load pinch valves; or optional patented Oden Microdose® filling valves.

High-Quality Gravity Filling Machines from Oden

Oden’s liquid gravity fillers are designed for volumetric timing filling. The elevated tanks on this bottle filler hold the product until the container has been placed underneath the filling nozzles. The nozzles then opened the product for a specified time period. Each fillhead is timed individually so that the volumetric fill of the bottle is accurate. Gravity fillers, either automated liquid fillers or semi-automatic ones are best suited to liquids of low viscosity strength. Various gravity filler nozzles also help prevent drips and help reduce foam.

How Does a Gravity Filling Machine Work?

Gravity filling is the easiest filling technique. It has no complicated construction operation, allowing gravity filled equipment to operate in fewer maintenance. The supply tanks (also known as fillings) represent the upper and center of the machine. Filling stems are attached at each container's filling point. The nozzle extends upward through the filler to the point below the water level. In order to start loading the container has to be raised up on its platform and contact the nozzles in the tank. The platform then raises the containers against the stem and opens the filler valve.

In sizing the bottles, gravity fill machines allow re-filling the bottles to the same amount using a time-based filling principle. Once again referring to the discrepancies within the internal volume of containers, gravity fillers ensure every bottle container has the same quantity of product. While machines that have gravity can be equipped with various nozzles in different sizes and shapes, they normally open for a predetermined period of time to allow a product to pass through.

Gravity Filler Principle

Its operation is performed using pneumatic valves in a holding tank. Several valves are individually controlled by a specialized computer that controls the filling process so that precise quantities flow from the container in an instant. Gravity Filler systems with bottom-up fill capability can handle all sorts of fluids such as foam. Application: This filling type is most suitable for fluids with a thin viscosity that cannot vary with ambient temperatures or with batches. Moreover, these machines are suited for applications where liquid recirculation in flow is not required.

Features & Benefits of Gravity Filling Machines

When you purchase gravity filling equipment from Oden Machinery, you gain access to a wide range of advantages attributed to our top-notch machinery. At Oden, we are committed to delivering unwavering quality backed by dependable construction and seamless installation, ultimately optimizing your operations and bottom line.

Some of the features of our gravity filling machines include:

- Durable machinery that’s built to last

- Seamless installation and integration

- Automatic and semiautomatic machines available

- Custom configurations and features

- Options available for sanitary environments

Optional Gravity Filling Machine Features

Our equipment comes with standard features suitable for a wide range of facility requirements. However, our gravity filler product line also offers optional features, ensuring complete customization. With our customizable configurations and size options, you can get everything you need and stay within budget.

Applications for Gravity Filling Machines

You can use our gravity fillers for a variety of liquid products, including:

- Personal care, health, and beauty

- Liquid foods and sauces

- Water, juice, and beverages

- Pharmaceuticals

- Chemicals

- Cleaning supplies

- Paints, stains, and sealants

- And more!

Regardless of your specific application, we are committed to helping you find the ideal equipment for your products. We offer an array of options tailored to the specifications of your packaging systems, ensuring an optimal match for your requirements.

Browse Our Gravity Filling Machines & Request a Quote

Begin your equipment search for your facility by exploring our selection of gravity filling machines. For more information on any of our products, including pricing details, please feel free to reach out to us anytime. We are available to offer comprehensive information along with a complimentary quote.