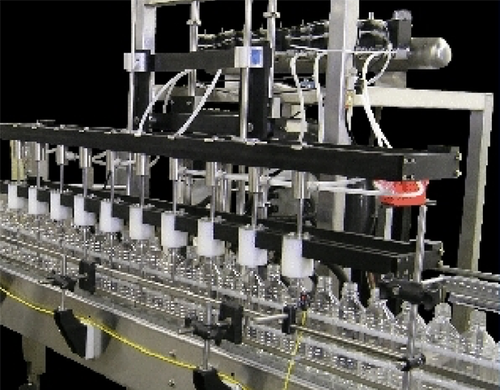

Oden Air Rinsers provide an efficient way to safely remove dust and small particles from containers before filling. This system is particularly suitable for removing loose contaminants that may have accumulated in the containers during shipping or storage. Containers first enter the rinsing area and are then bathed with ionized air generated by special transvector air flow amplifiers. The static charge that attracts debris to the surface of the containers is neutralized (ionized air does not sterilize the containers). Rinsing heads are lowered into the containers and a blast of compressed air is blown into them. A vacuum is then applied to remove the loose particulate. Debris is collected in a bag behind the machine or directed into the extraction system of the facility.

Benefits

- Ionized air, Compressed air and vacuum

- Flexible, Simple changeover

- Removes the static charge that causes dust to be attracted to the sides of containers, allowing the debris to be removed

- High pressure filtered air combined with a vacuum maximize the removal of loose contaminants from containers. Because the system uses air, no rinsing solution is left to contaminate the container when the rinse cycle is complete

- Versatility and simplicity are intrinsic to the design.

- Many container shapes and sizes can be run on one machine

- Manufactured with few or no change parts allows for easy changeover and minimal downtime

Standard Specifications

- Frames are typically 304 stainless steel

- PLC controls with user-friendly setup

- Vacuum dust suction nozzles with coned, self-centering neck guides

- Stainless steel leveling legs

- Manual height adjustment

- Automatic pin-style indexing

- Photo sensor/counter system to ensure containers are in place prior to filling

Optional Components

- 316 stainless steel construction upgrade

- Star wheel or timing screw indexing system

- Ability to integrate control system into the filler for easy setup and operation

Applications

- Glass, metal and plastic containers

- Virtually all containers up to 1 gallon

- Beverages

- Food products

- Personal care products

- Chemicals